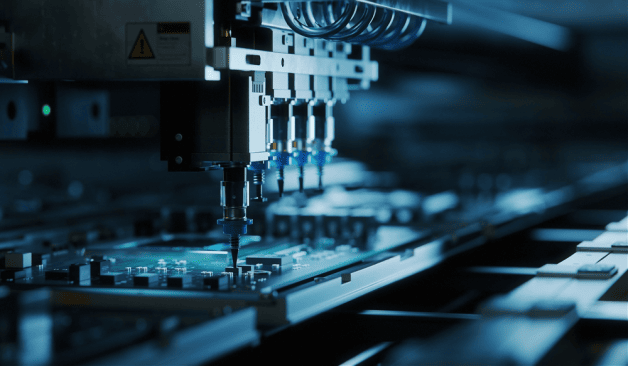

India and increasing Electronic Production: Entry of Global Tech companies

There are over 650 million smartphone users in India. Have you ever thought about how much effort goes into making a smartphone? A lot! As per a recent report, the Wi-fi and Bluetooth alone - two small components in your smartphone - get manufactured in country X and then cross 70 international borders before they reach your home in India. How long does it take for the entire process? It can take up to 100 days, and nearly two weeks are spent between various supply chains.

So much goes into the making of the phone, and until now, most of this development has been done in South Asian countries like Taiwan, China, South Korea, and the United States. However, the landscape of electronic production for smartphones is going to change.

India wants to become a global electronics manufacturing hub. For starters, what is happening is that different electronics component makers are setting up their manufacturing units in India. But before we get into the details of companies setting up their units in India, we need to understand why it is happening now. What has changed in recent years that has prompted the government to think in this direction?

Why is the Indian government pushing for electronic production?

Here are some reasons for this:

- Reducing Dependency: Currently, India relies heavily on imports of electronic goods and components. The heavy dependency on imports can pose risks to national security and economic stability, especially in times of geopolitical tensions or disruptions in global supply chains. By promoting domestic production, India aims to reduce its dependency on foreign nations for critical technologies.

- Job Creation: Establishing domestic manufacturing facilities for electronics and semiconductor production can lead to the creation of a significant number of jobs across various skill levels. It aligns with the government's goal of fostering employment opportunities and boosting economic growth.

- Attracting Investments: Building a robust domestic manufacturing ecosystem can attract domestic and foreign investments. It can spur innovation, technology transfer, and the development of ancillary industries, further enhancing India's position as a global manufacturing hub.

- Trade Balance Improvement: India's large electronics imports may contribute significantly to its trade deficit. By boosting domestic production, the government aims to narrow this gap, potentially improving the country's overall trade balance.

- Strategic Autonomy: Having a robust domestic manufacturing base for electronics and semiconductors enhances India's strategic autonomy by reducing reliance on external sources for critical technologies. It is particularly important in sectors with implications for national security and defense.

Who is setting up shops in India?

Do you know the largest supplier of electronic components for Apple? They are Foxconn and Pegatron. These companies have operations in India. Foxconn has invested huge amounts to expand its manufacturing footprint in India - they plan to deploy Rs 1,200 crore in India for their new factory setup. Additionally, the company has announced that it will inject $2.7 billion. Through this investment, it plans to start iPhone production by April 2024 in India.

Also, as per reports, Rayprus, a subsidiary of Foxconn, is looking to enter India. Apple's other supplier, Wistron, which has a facility in Karnataka, has been taken over by Tata Electronics to expand its capability in contract manufacturing of high-end electronic items and accessories.

Apple’s supplier, Corning, has committed to setting up a new facility for the production of cover glass in Tamil Nadu at an investment of Rs 1,000 crore.

Apple’s only Indian vendor, Tata Electronics, is looking to expand its existing Hosur facility and has committed a large sum to further its electronics manufacturing ambitions while also taking over the Wistron facility in Karnataka to scale up its capacity.

Why the shift - companies coming to India?

If you are wondering why these international giants are shifting focus here, there are reasons behind it. Let us look at some of the reasons:

- Geopolitical Landscape: Recent geopolitical tensions and trade uncertainties have prompted many companies to diversify their manufacturing operations away from regions that are prone to instability or trade disputes. India with its large domestic market and stable political environment, offers an attractive alternative for companies looking to mitigate the geopolitical risks associated with their supply chains.

- Strengthening Supply Chain: Establishing manufacturing units in India allows electronic companies to strengthen their supply chains by reducing dependency on a single manufacturing location. By diversifying production geographically, these companies can enhance resilience against disruptions such as natural disasters, pandemic-like situations we saw recently, geopolitical tensions, or trade barriers.

- Localization Angle: India's government has been actively promoting local manufacturing through initiatives like 'Make in India'. By setting up units in India, electronic companies can cater to the rapidly growing Indian market while also complying with local regulations, including requirements for localization, which may involve sourcing components or labor locally.

Before you go

With all the investments coming in through these companies, it will be a sure boost for the Indian manufacturing sector. However, the setting up of these units is only half the battle won. The government and Indian companies will have to work towards designing and acquiring intellectual property from India. Yes, it is not an easy path, but we will have to take it.